The chemical industry is marching forward with its spending of $1 trillion now through 2030 to build new capacity (globally) to meet the ever-growing demand of fundamental feedstocks and their derivatives. As such, decisions surrounding the deployment of this capital become ever more important as sustainability seems to be a moving target. Sustainability encompasses many aspects beyond investment and operating cost, which includes:

While many of these aspects are outside of the control of the operators/stake holders, the deployment of capital in an efficient and responsible manner is within their control.

Specifically, capital investment costs continue to be at the center of a company's long-term sustainability. This especially takes in account the growth in the scale of plant capacities - e.g., current announcements of nearly 2 million metric tons per year ethylene plants as well as 4.3 million ton per year p-xylene-based mega Crude-oil-Chemical plants in China (a philosophy of "go big or go home".)

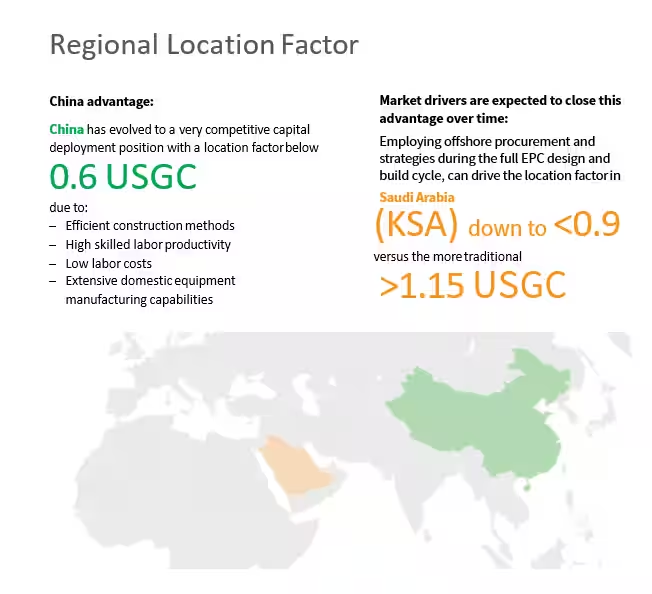

A more recent critical dimension of capital deployment impact is the relative cost in a country to build an equivalent technology/capacity (location factors). The IHS Markit Process and Economics Program (PEP) team is seeing that leading companies have, and will continue to take advantage of - local costs, macroeconomics and country infrastructure within each of the engineering, procurement and construction phases of a product development to achieve a high capital deployment efficiency (i.e. low cost per ton of installed capacity).

Examples of this realized advantage are illustrated below:

IHS Markit Process and Economics Program (PEP) has packaged five essential relevant reports/reviews as a part of our continuing technology and economics PEP offering on Capital Deployment:

Download a sneak peak to some of our analyses

Posted 24 July 2019 by Don Bari, Vice President, Technology and Analytics Group (TAG), S&P Global Commodity Insights

© by S&P Global Inc. All rights reserved.